Views: 0 Author: Site Editor Publish Time: 2025-09-03 Origin: Site

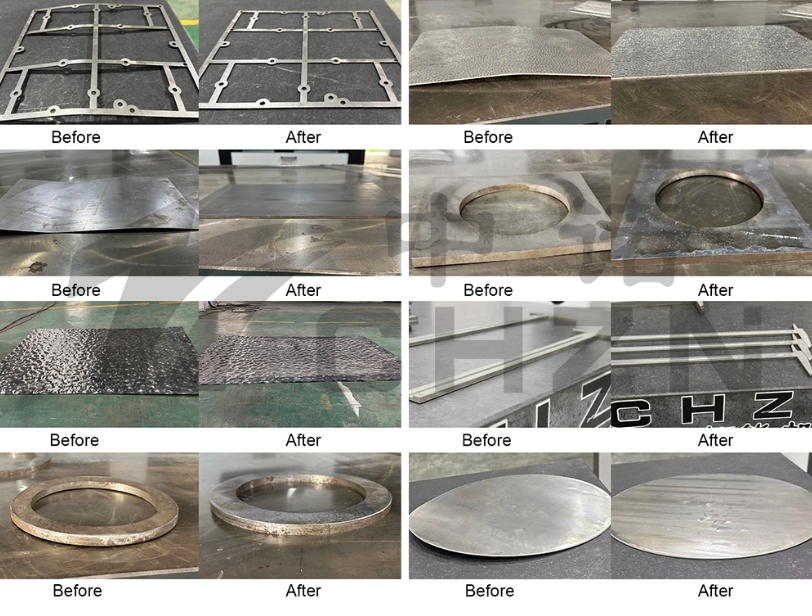

In today’s steel and metalworking industries, achieving flat and uniform sheets is a fundamental requirement. This is where the Sheet Leveling Machine comes into play. Designed to eliminate imperfections such as waves, buckles, and internal stresses, this machine ensures that sheets are ready for downstream processes including cutting, welding, stamping, and coating. By understanding how sheet leveling works and the advantages it provides, manufacturers can optimize production efficiency and deliver products that meet the highest quality standards.

A sheet leveling machine is a crucial piece of industrial equipment designed to flatten and stabilize metal sheets or coils. During steel production processes such as hot rolling, cold rolling, and annealing, materials often develop residual stresses, waviness, or surface distortions. These imperfections can significantly impact the quality and usability of the metal sheets in downstream manufacturing processes. Therefore, sheet leveling machines play a vital role in ensuring that the metal sheets meet the required standards of flatness, dimensional accuracy, and overall quality.

Improving Flatness:

Residual Stresses: During the production process, metal sheets can develop internal stresses that cause warping, bowing, or buckling. Sheet leveling machines correct these imperfections by applying controlled mechanical force, resulting in a flat and uniform surface.

Surface Distortions: Processes like hot rolling and cold rolling can leave metal sheets with uneven surfaces or waviness. Leveling machines address these issues, ensuring that the sheets are smooth and free from distortions.

Relieving Internal Stress:

Material Stability: Residual stresses can lead to material instability and inconsistencies during further processing. By relieving these stresses, sheet leveling machines enhance the overall stability and reliability of the metal sheets.

Preventing Deformations: Proper leveling helps prevent deformations that might occur during subsequent manufacturing steps, such as cutting, welding, or forming.

Ensuring Dimensional Accuracy:

Precision Requirements: Many manufacturing applications require metal sheets to meet precise dimensional specifications. Sheet leveling machines ensure that the sheets are flat and uniform, meeting these stringent requirements.

Consistency: By maintaining consistent dimensions, leveling machines help reduce waste and improve the efficiency of downstream processes.

After the leveling process, additional operations are often performed to ensure the final product meets all required specifications:

Cutting to Length: The leveled sheet is cut to the desired length using precision cutting tools. This ensures consistency in final dimensions, which is crucial for subsequent fabrication processes.

Edge Trimming: Any irregularities or burrs along the edges of the sheet are removed to produce clean, smooth edges.

Quality Inspection: The leveled sheet undergoes a thorough inspection to verify its flatness, thickness uniformity, and overall quality. This may involve visual inspection, measurement with precision instruments, or non-destructive testing methods.

Sheet leveling machines are essential tools in metalworking and manufacturing. They are designed to correct imperfections in metal sheets, such as warping, bowing, and buckling, to achieve a flat and uniform surface. The choice of leveling method depends on factors like sheet thickness, material type, and the specific requirements of the end product. Here’s a more detailed look at the common leveling methods:

In roller leveling, the metal sheet passes through a series of alternating upper and lower rollers. The rollers are arranged in a staggered pattern, with the upper rollers slightly offset from the lower ones. As the sheet moves through the machine, it is alternately bent and released multiple times. This repeated bending action redistributes internal stresses within the material, effectively correcting any imperfections and producing a flat surface. This method is suitable for a wide range of sheet thicknesses, from thin foils to thicker plates, and is commonly used in industries such as automotive, aerospace, and general manufacturing. It can handle various materials, including steel, aluminum, and stainless steel, and provides a high degree of flexibility in terms of sheet size and thickness. It is also relatively cost-effective compared to some other methods. However, it may not be as effective for extremely thick sheets or those with severe deformations, and it requires careful adjustment of roller settings to achieve optimal results.

Cold rolling leveling involves passing the metal sheet through rollers at or near room temperature. The process applies significant pressure to the sheet, causing it to deform plastically. This method not only flattens the sheet but also improves its surface finish and mechanical properties, such as strength and hardness. It is ideal for applications where surface quality and precision are critical, such as in the production of high-quality steel sheets for automotive body panels or precision engineering components. The advantages of this method include achieving superior surface quality with minimal defects and enhancing the mechanical properties of the material, making it stronger and more durable. However, it is more expensive due to the high precision and control required, and it is limited to thinner sheets, as thicker materials may require excessive force and energy.

Hot rolling leveling involves heating the metal sheet above its recrystallization temperature before passing it through the leveling rollers. This process softens the material, making it more ductile and easier to deform. The heat also helps to relieve internal stresses and improve the overall uniformity of the sheet. It is commonly used for thicker sheets and plates, particularly in industries such as construction, shipbuilding, and heavy machinery manufacturing. The advantages of this method include its effectiveness for thicker materials that are difficult to level using cold rolling methods and its cost-efficiency for mass production due to the ability to process large volumes of material quickly. However, it requires significant energy for heating, which can increase operational costs, and the heat treatment process may affect the material’s microstructure and properties, requiring careful control.

Tension leveling involves stretching the metal sheet between two tension reels until it reaches a point just beyond its yield strength. This stretching action eliminates residual stresses and corrects any distortions, resulting in a highly flat and uniform sheet. It is particularly effective for cold-rolled sheets that require high levels of flatness and dimensional accuracy and is used in industries such as electronics, where precise sheet dimensions are crucial. The advantages of this method include achieving excellent flatness and significantly reducing residual stresses, providing consistent results suitable for high-precision applications. However, it is limited to thinner sheets, as thicker materials may be too rigid to stretch effectively, and it requires precise control of tension to avoid over-stretching and material damage.

Temper leveling combines the principles of roller leveling and tension leveling. The sheet is first subjected to a series of rollers to redistribute stresses, followed by tensioning to further enhance flatness and thickness uniformity. This hybrid approach provides the benefits of both methods, making it highly effective for a wide range of materials and thicknesses. It is suitable for thicker hot-rolled sheets that require improved flatness and thickness uniformity and is commonly used in industries such as steel production and heavy machinery manufacturing. The advantages of this method include enhancing both flatness and thickness uniformity, making it suitable for demanding applications, and providing a versatile solution that can handle a variety of material types and thicknesses. However, it is more complex and expensive compared to simpler leveling methods and requires careful calibration and control to achieve optimal results.

Stretcher leveling uses hydraulic cylinders to pull the metal sheet in multiple directions until the internal stresses are completely relieved. This process produces sheets with exceptional flatness and uniformity, making them suitable for the most demanding applications. It is ideal for high-precision applications such as aerospace components, heavy machinery parts, and precision engineering. The advantages of this method include achieving the highest level of flatness and uniformity among all leveling methods and being suitable for materials with severe deformations or high internal stresses. However, it is very expensive due to the high precision and advanced technology required and is limited to specific materials and thicknesses, as not all materials can withstand the intense stretching forces.

| Leveling Method | Principle | Applications | Advantages | Limitations |

|---|---|---|---|---|

| Roller Leveling | Alternating bending and releasing through multiple rollers | Wide range of sheet thicknesses, automotive, aerospace, general manufacturing | Handles various materials, flexible, cost-effective | Less effective for extremely thick sheets or severe deformations |

| Cold Rolling Leveling | Passing sheet through rollers at room temperature | High-quality surface finish, precision engineering components | Superior surface quality, improved mechanical properties | More expensive, limited to thinner sheets |

| Hot Rolling Leveling | Heating sheet above recrystallization temperature before rolling | Thicker sheets, construction, shipbuilding, heavy machinery | Effective for thick materials, cost-efficient for mass production | Requires significant energy for heating, may affect material properties |

| Tension Leveling | Stretching sheet between tension reels beyond yield point | Cold-rolled sheets, electronics, high-precision applications | Excellent flatness, reduces residual stresses | Limited to thinner sheets, requires precise tension control |

| Temper Leveling | Combines roller leveling with tension leveling | Thicker hot-rolled sheets, steel production, heavy machinery | Enhances flatness and thickness uniformity, versatile | More complex and expensive, requires careful calibration |

| Stretcher Leveling | Pulling sheet in multiple directions using hydraulic cylinders | Aerospace components, heavy machinery parts, precision engineering | Achieves highest level of flatness and uniformity | Very expensive, limited to specific materials and thicknesses |

When selecting a sheet leveling machine, several factors should be considered:

Material type – mild steel, stainless steel, aluminum, or high-strength alloys.

Sheet thickness range – from thin-gauge precision sheets to heavy plates.

Production volume – whether for small-batch high-precision work or high-speed industrial production.

Automation level – integration with coil feeding lines, cutting-to-length lines, or robotic handling systems.

Cost-efficiency – balancing surface quality requirements with production costs.

A: A sheet leveling machine is used to flatten and stabilize metal sheets or coils, correcting imperfections like residual stresses, waviness, and surface distortions to ensure the material meets dimensional accuracy standards.

A: Cold rolling leveling is used for high-precision applications where surface quality and strength are critical. It involves passing the sheet through rollers at room temperature to achieve a superior surface finish.

A: Hot rolling leveling is effective for thicker sheets and plates. It softens the material by heating it above its recrystallization temperature, making it easier to level and improving overall uniformity.

A: Tension leveling involves stretching the metal sheet between tension reels to eliminate residual stresses and correct distortions. It is particularly effective for cold-rolled sheets requiring high levels of flatness and dimensional accuracy.

A: After leveling, the sheet is typically cut to length, edge-trimmed to remove irregularities, and inspected for quality to ensure it meets the required standards of flatness and uniformity.

A sheet leveling machine is more than just auxiliary equipment—it is an essential part of the steel and metal processing industry. By delivering flat, stress-free, and dimensionally accurate sheets, it ensures smoother downstream fabrication, higher productivity, and better product quality.

If you want to achieve high-quality steel sheets for your projects, consider partnering with Zhejiang Zhongnuo Intelligent Machinery Co., Ltd. Our advanced technology and reliable service will help you meet your production goals with confidence.