Introduction to Metal Deburring Machine

A metal deburring machine is a specialized tool used in manufacturing to remove burrs—sharp, unwanted edges left on metal parts after cutting, milling, or machining. These machines work by applying abrasives, brushes, or other mechanical means to smooth the edges, ensuring that the part is safe to handle, functional for assembly, and aesthetically polished.

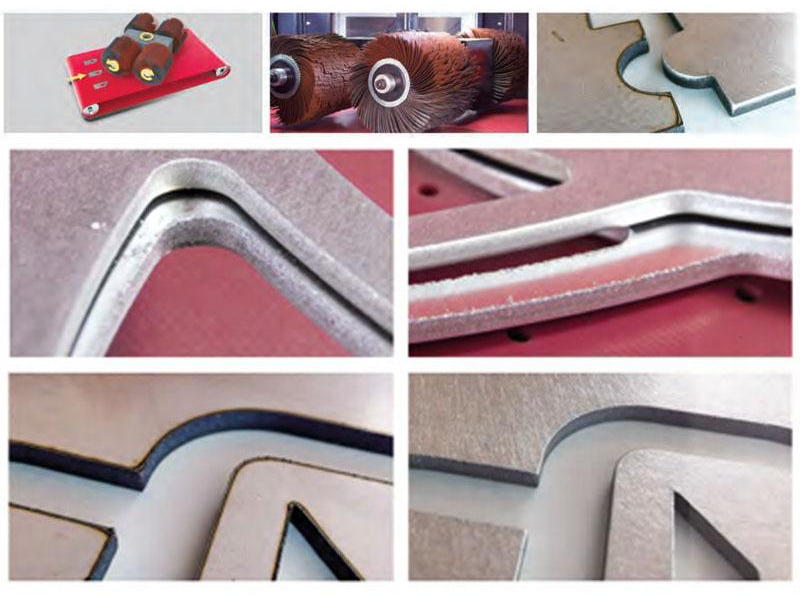

Product Showcase

Material and Performance

Metal deburring machines are designed to work with a wide range of materials, including:

● Aluminum: A soft metal that requires gentle deburring techniques to avoid excessive wear on the machine.

● Steel: Stronger metals like steel require more powerful abrasives and pressure settings for efficient burr removal.

● Copper: Deburring copper requires specialized machines that prevent damage to the softer metal.

● Exotic Alloys: Harder materials like titanium or Inconel require high precision and often benefit from advanced machines with CNC control.

Types of Deburring Machines

● Rotary Brush Machines: These machines are best for handling delicate parts and intricate shapes, making them ideal for industries like aerospace and automotive.

● Belt Grinding Machines: These are suited for heavy-duty deburring, especially for thicker materials.

● Vibratory and Tumbling Machines: These machines are used for mass processing small parts, perfect for high-volume production.

● Wet vs. Dry Machines: Wet deburring machines use liquids like coolant to prevent heat buildup, while dry machines are faster and ideal for materials that don’t require cooling.

Why Choose Our Metal Deburring Machine?

Reliable Performance

Our deburring machines are built for consistent, high-quality results, ensuring your parts meet industry standards.

Expert Support

We provide comprehensive customer service, including installation assistance, troubleshooting, and ongoing maintenance support.

Increased Efficiency

Our machines automate the deburring process, significantly speeding up production while minimizing labor costs.

Precision and Consistency

With advanced CNC controls, our machines deliver repeatable, precise results, ideal for industries requiring tight tolerances.

Durability and Cost-Effectiveness

Built with high-quality materials, our machines are designed for long-term use, offering a great return on investment through reduced downtime and maintenance costs.

Frequently Asked Questions (FAQs)

How long does a deburring machine last?

How long does a deburring machine last?

Related Blog

-

In today's fast-paced manufacturing industry, precision and efficiency are paramount. To achieve impeccable results, companies are constantly seeking innovative solutions. One such solution that has gained significant attention is the new metal deburring machine. With its advanced technology and sta

In today's fast-paced manufacturing industry, precision and efficiency are paramount. To achieve impeccable results, companies are constantly seeking innovative solutions. One such solution that has gained significant attention is the new metal deburring machine. With its advanced technology and sta

English

English